Plastic Bottle Inspection Machine

Feature

- Easy Control: PC-based control system is equipped with HMI touch panel.

- Intelligent Setting: Quickly set up through auto-learning system and intelligent parameter.

- Online Instruction: System is built-in production line change instruction, the user does not need to read paper user manual.

- Effective Productivity: Checking speed is up to 250pcs/min.

- Customized Manufacture: The system is designed based on the different size, shape and color of bottles to reduce unnecessary adjustment.

- System is suitable to check both internal and external quality of bottles.

- Inspected Defects: Shortage, dirt, foreign matter, dents, deformation, scratches, and color difference.

- Defect Determination Adjustment: Every defect could be adjusted its accuracy individually.

- Statics Data: Enables to classify defective type and report to the production line to modify the high frequency defect.

- Machine Learning: Every new product could be set up quickly through machine learning system.

- Product Management: The adjusted parameter value could be stored into database and called out for using.

- Event Recorder: The operating behavior could be recorded by 24 hours monitoring that could trace back and modify the machine failures.

| Model No. |

Product Name |

Capacity (pcs/min) |

| VBT100 | Inline Bottle Inspection Machine | 100 |

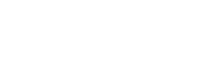

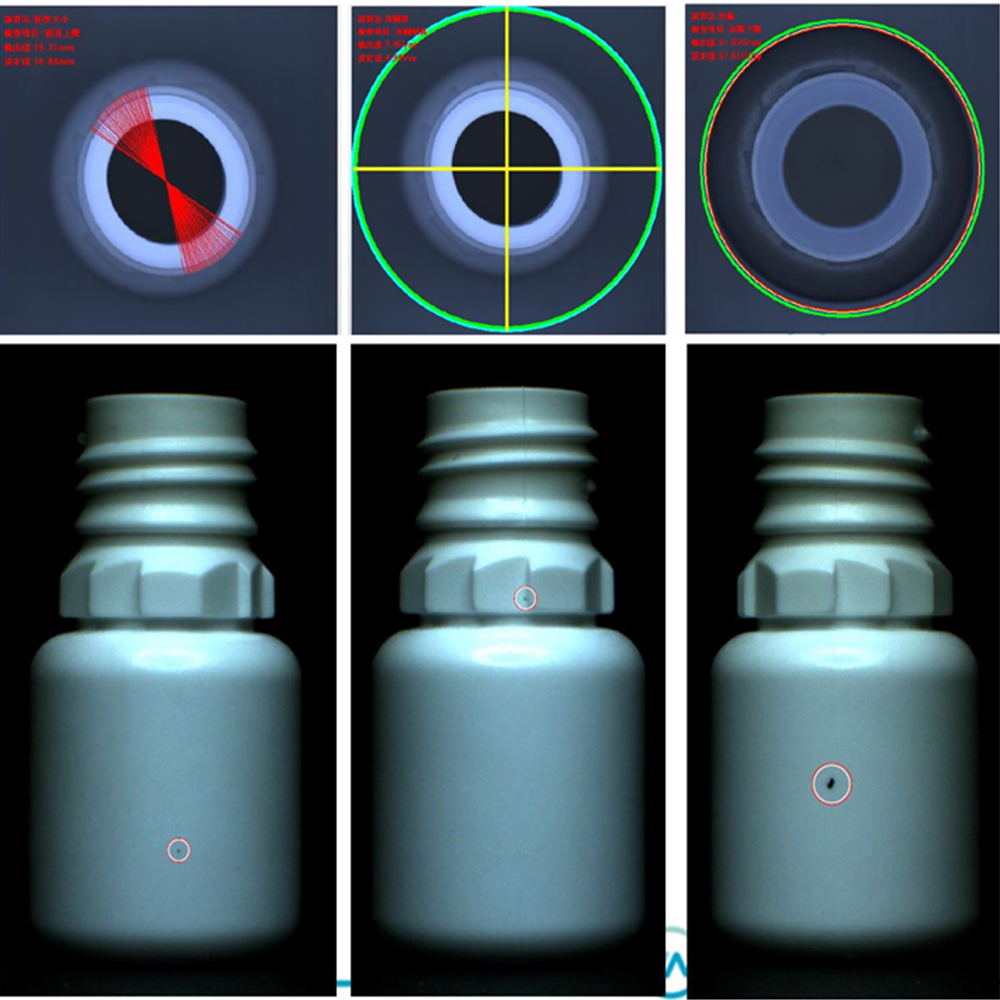

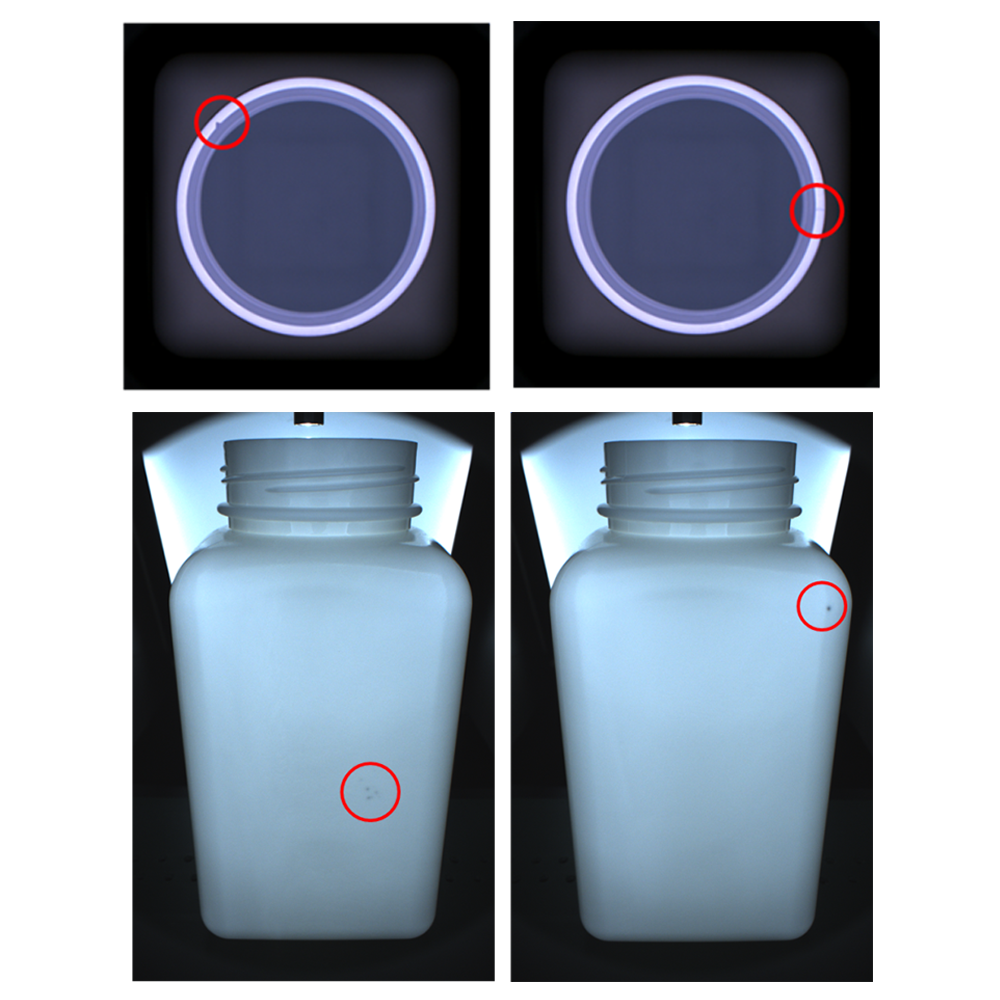

Medical Plastic Bottle-Execute comprehensively quality check for the bottle top side, neck, and body. The inspection items include contamination, foreign matter, broken, deformation, shortage, and color.

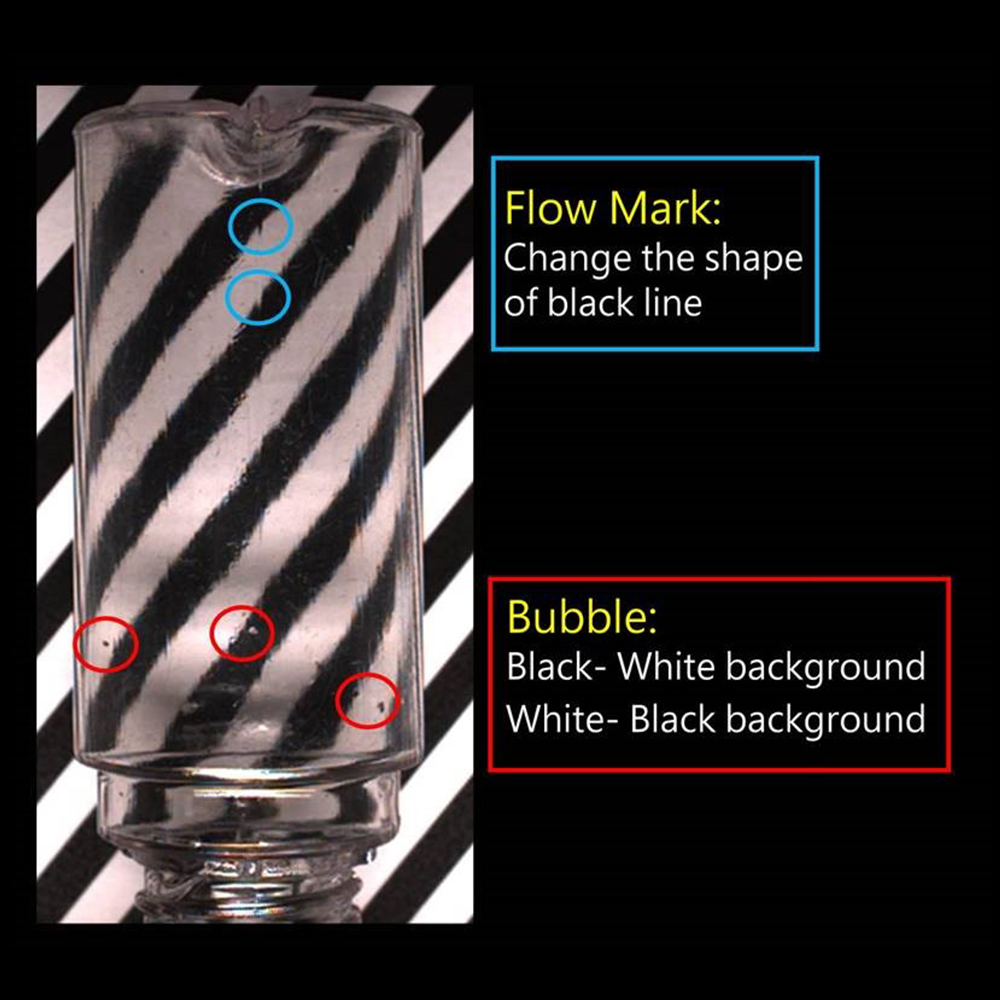

Cosmetic Bottle-Use special optics solution to inspect the transparent bottle. The tricky defects like bubble and flow mark will be detected easily.