Car Parts Inspection Machine

Feature

- 360゚Full side inspection: Multiple optical modules are used to check the top, side, and bottom of parts. All defects can be detected and rejected.

- System integration: Using conveyor to connect the injection molding machine. After molding, the parts can process quality check directly and then packing. This complete production line can enhance production efficiency and speed, and also reduce the pollution and damage caused by human contact.

- Easy to operate: All system can be controlled by computer to facilitate user operation.

- Strong and durable mechanical structure: The main body is made up of stainless steel to ensure production quality from pollution.

- Auto-packing conveyor: The number of parts and boxes can be set according to customer requirements to reduce labor cost.

- This system is equipped with numbers of optical modules to do comprehensive inspection. The product quality could be controlled strictly.

- Provide statistical data such as the average or maximum value of product, each defect item and quantity. Those data can be fed back to the manager to control and solve the problem of production line.

- This system can connect to the front molding machine and final auto-packing system to efficiency the production capacity and quality.

| Model No. |

Product Name |

Max. Capacity (pcs/min) |

| VCL100 | Inline Closure Inspection Machine | 3000 |

| VCL200 | Offline Closure Inspection Machine with Centrifugal Sorter | 1000 |

| VCL300 | Offline Closure Inspection Machine with Waterfall Sorter | 2000 |

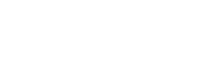

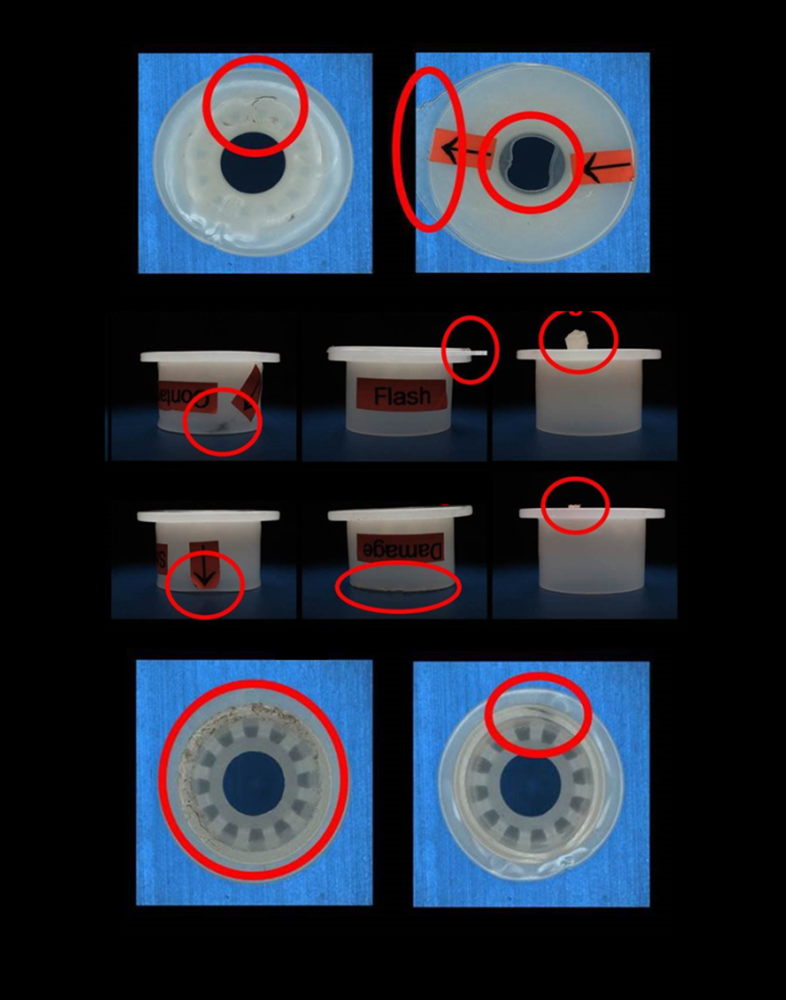

Car Parts Inspection-Use numbers optical modules to do 360゚full side inspection. The inspection items including contamination, foreign matter, broken, deformation, shortage, flash, and color.

Related Products