Filling & Packaging Inspection System

Feature

- Easy Control: PC-based control system is equipped with HMI touch panel.

- Quick Adjustment: Quickly set up through auto-learning system and intelligent parameter.

- Multi Application: Automated machine learning system. System could be set up and change easily to fit various production lines.

- High Flexibility: The system is compatible with multiple cameras to improve flexibility and quick setting.

- Customized Manufacture: System customization and integration could be performed based on the customer production line and product type to enhance detection efficiency.

- Quality Monitor:Enables to report the statistical data to increase the yield.

- System is suitable to inspection the filling or packaging quality of beverage, medical and cosmetic products.

- Inspection Items: Label, liquid level, capping and coding.

- IML inspection system is used to check after labeling. The main inspected algorithm includes foreign matter, stain, color, size, circularity, label stitching, missing label, crooked label, double label, label is drilled into injection goods.

- Defect Determination Adjustment: Every defect could be adjusted its accuracy individually.

- Statics Data: Enables to classify defective type and report to the production line to apply modification based on the defects.

- Machine Learning: Every new product could be set up quickly through machine learning system.

- Product Management: The adjusted parameter value could be stored into database and called out for using.

- Event Recorder: The operating behavior could be recorded by 24 hours monitoring that could trace back and modify the machine failures.

- Inspection Technique:

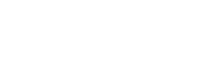

| Label Inspection- 360゚Label 2D Reconstruction | |

|

|

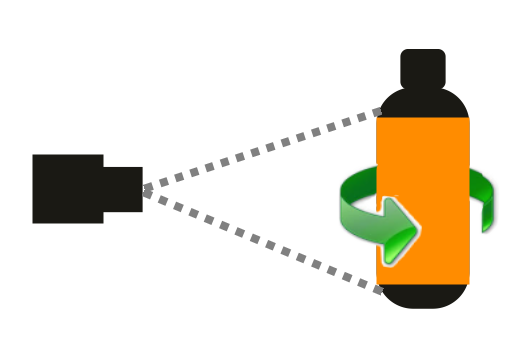

| Liquid Level Inspection- Area Match Technique | |

|

|

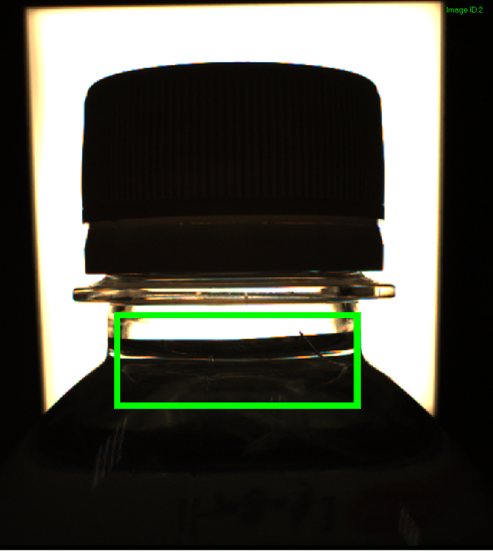

| Capping Inspection- Location & Shape Detection | |

|

|

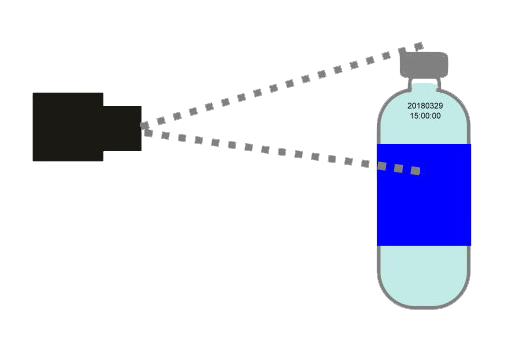

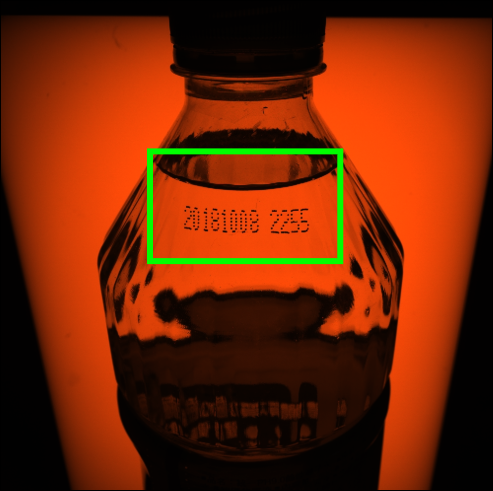

| Coding Inspection- Location & Character Recognition | |

|

|

| Model No. |

Product Name |

Max. Capacity (pcs/min) |

| VFL100 | Filling Line Inspection Machine | 400 |

Related Products