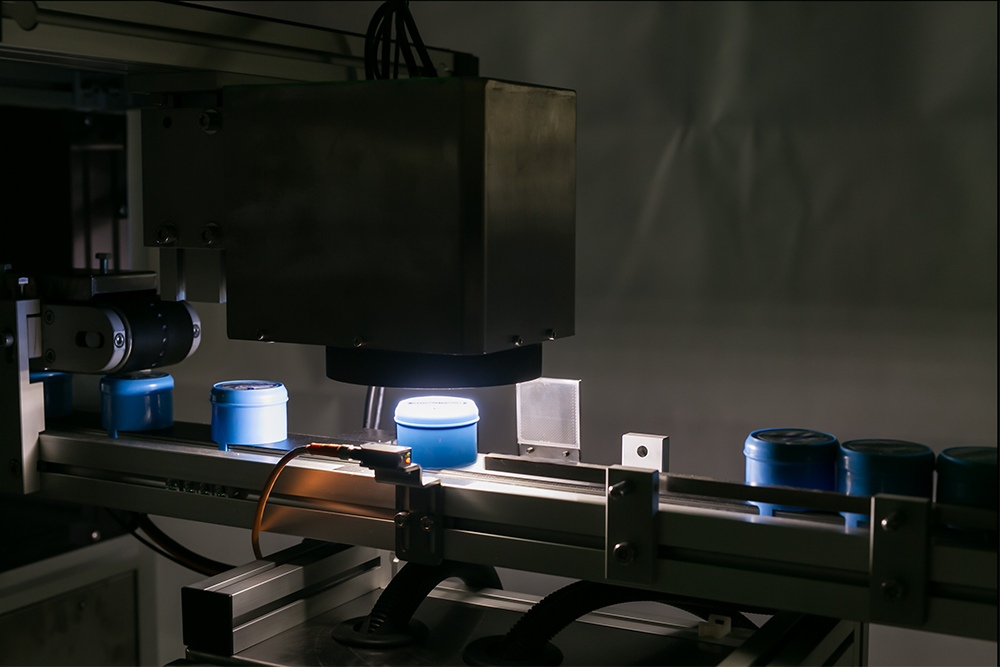

High Speed Closure Inspection System

Feature

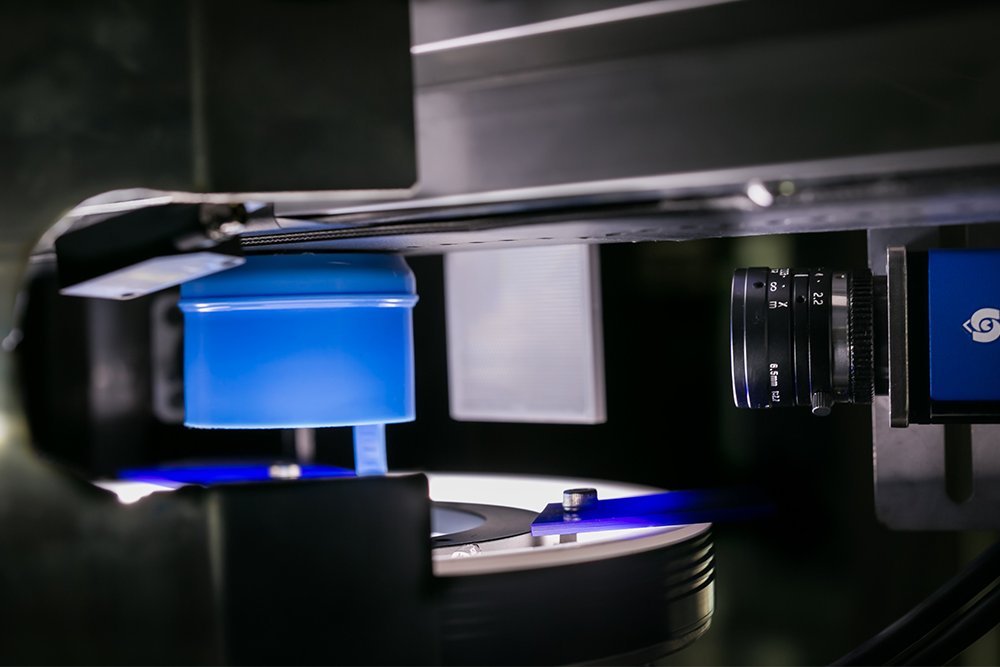

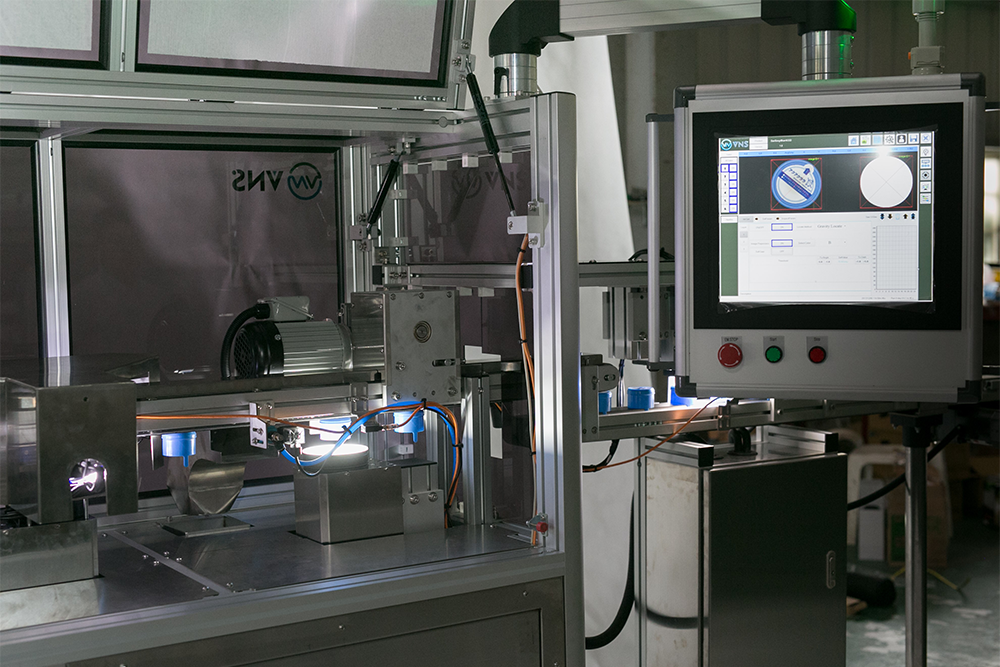

- The computer control system with touchable human machine interface.

- Simple and quick adjusting the required closure size.

- High efficiency capacity, fastest up to 3000pcs/min.

- The main body is made up of stainless steel to ensure production quality from pollution.

- Self-learning image processing technology , easily to adjust.

- 100% shaving defective products.

- Customization of integrating the closure line-cutting machine and the folding machine as well as the backside process quality monitoring.

- High speed closure inspection system is suitable for detecting internal quality of plastic closures after cutting ring and folding its edge, with the speed up to 3000pcs / mm.

-

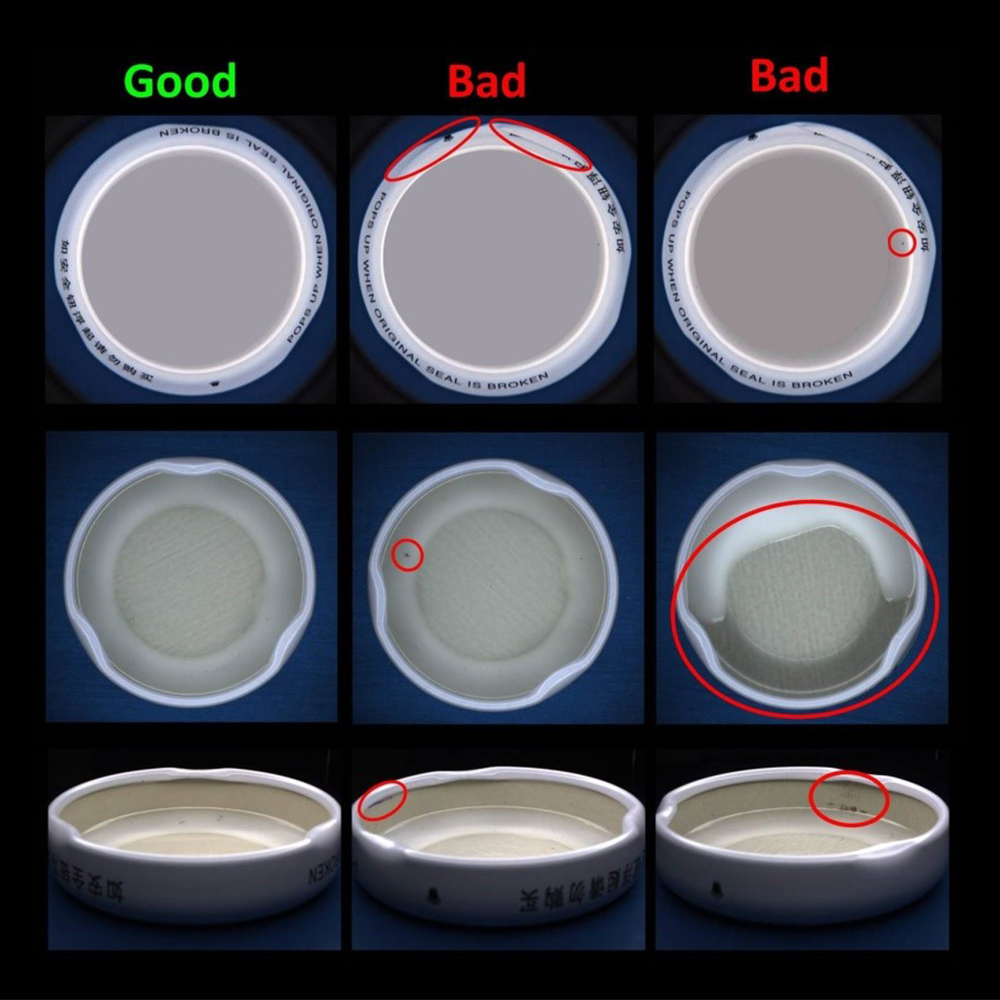

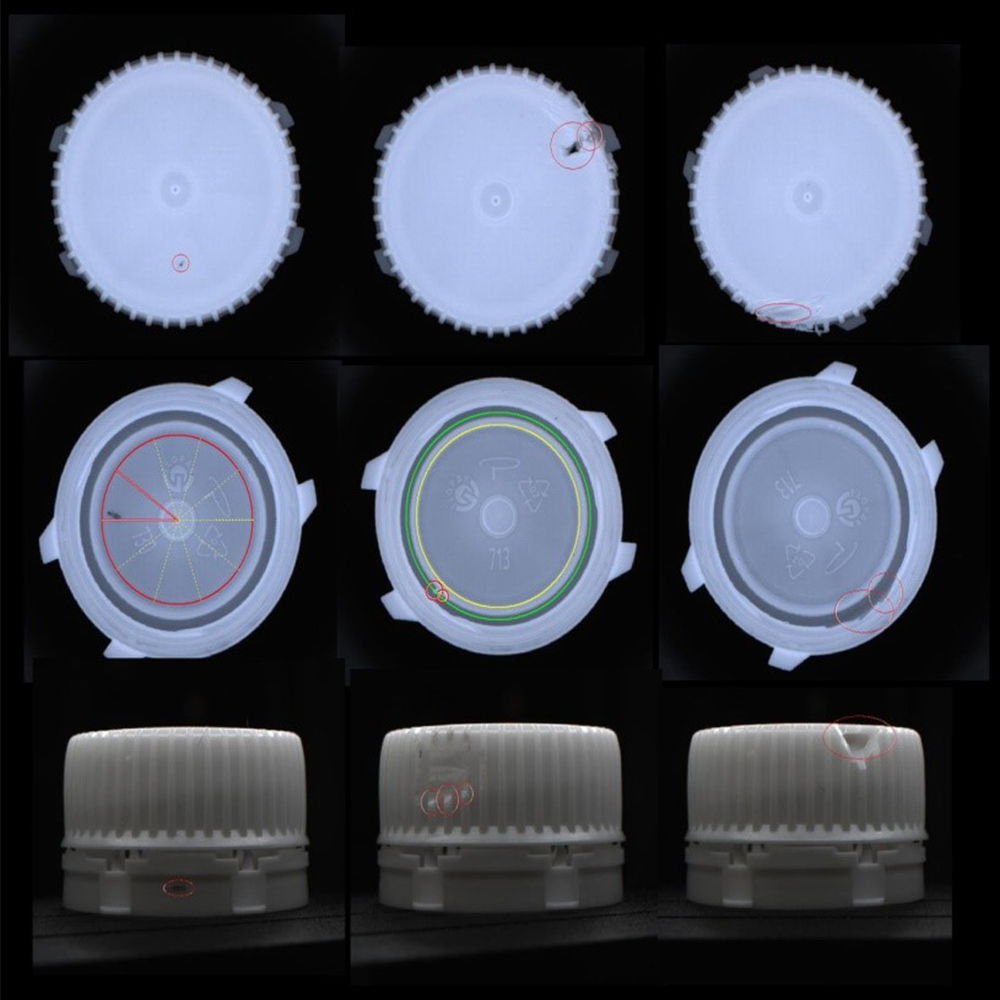

This system can inspect defective closures, such as:

closures with visible burr, stains, and shapeless, distorted and deformed parts, parts which cannot meet the standard size, and oval closures. - This system provides statistical information, such as the number of the lid, the average value and the maximum value of the production, high-quality closure information, the total data of the defective lid, the lid with different defecting items, and the maximum number of consecutive defective closures.

| Model No. |

Product Name |

Max. Capacity (pcs/min) |

| VCL100 | Inline Closure Inspection Machine | 3000 |

| VCL200 | Offline Closure Inspection Machine with Centrifugal Sorter | 1000 |

| VCL300 | Offline Closure Inspection Machine with Waterfall Sorter | 2000 |

5 Gallon Closure Inspection-360゚full side inspection including cosmetic, shape, dimension, and label defects.

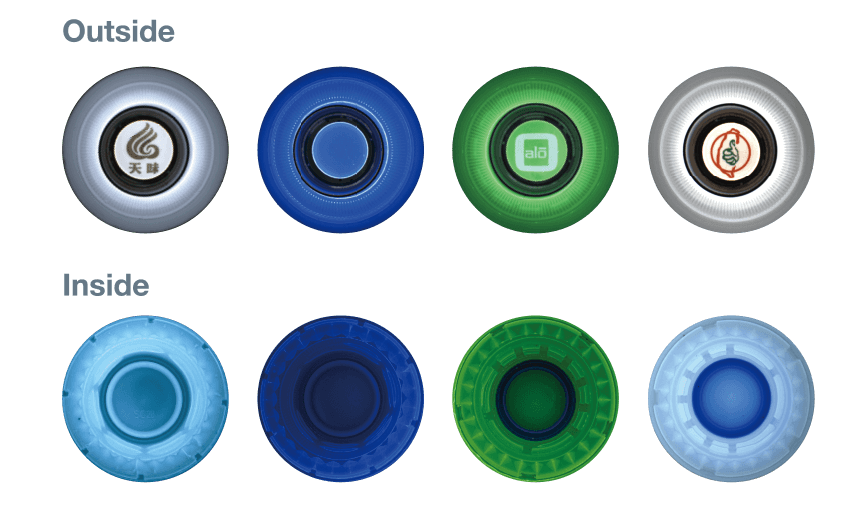

Assembled Closure Inspection-This system enables to inspection the top cap, bottom spout, and assembled closure through one machine. The closure quality could be controlled completed before and after assembling. The defective items including size, deform, short shot, dent, seal, foreign matter, damage.

Metal Cap/ Jar Inspection-System solve the problem that the metal material is easy to reflect and scratch, and it can effectively execute comprehensive quality check. The detected defective items contain dent, deform, scratch, foreign matter, contamination, spilled glue, and printing.